Pole Mounting Best Practices: A Regional Guide for Telecom and Solar Installers

January 15.2026

Global rollout teams don’t lose time because crews can’t mount equipment. They lose time because mounting outcomes vary from site, crew, and climate. Fastening methods and materials need to be standardized, so installs stay secure in any environment.

Early Mounting Problems Can Lead to Costly Repairs

Initial installations often pass first inspection, only to develop into problems as time goes on. A bracket shifts after vibration or thermal cycling, a clamp relaxes because tension was inconsistent, corrosion starts at an interface and slowly undermines the joint, the list goes on. Hardware is rarely the most expensive component but return visits, troubleshooting, access coordination, and schedule disruption can add up.

Mounting Faces a Variety of Challenges Across the Globe

In Asia and the Middle East, mounting solutions have to survive heat, dust, salt air, and quickly changing weather. In Europe, challenges often include crowded street hardware, tight clearances, and strict site acceptance expectations. In North and South America, wide temperature swings, freeze-thaw and remote access can make a second trip especially painful. Different regions amplify different stressors, but the same root issue drives different outcomes: Variation.

Define Success Before You Pick Hardware

If you’re an installer, success should mean the mount is tightly secured, stable, and long lasting. For equipment designers or sourcing teams, success should mean that the installation method is easy to train across crews and finished results are consistent no matter who is performing the installation.

Three Most Important Criteria in Sourcing:

- Repeatability that doesn’t depend on subjective judgement

A mounting method that relies on “Feel” produces different outcomes across installers and regions. Faster deployment schedules and denser hardware networks increase that risk because training time is limited. Processes that reduce guesswork will reduce rework.

- Equipment built to last in the field, not just the lab

Life in the field means constant exposure to water, dust, wind, UV, and corrosion. These are everyday realities, not exceptions. If your equipment is installed outdoors, the mounting method should be designed for outdoor stressors, not adapted after the fact.

- Designing to global standards accelerates rollout and adoption

You don’t need a standards lecture to mount a bracket, but you do need a design that travels. Aligning mounting hardware and installation methods to widely recognized standards specs simplifies documentation reuse across regions and reduces the need for local variants. That means faster acceptance and more consistent installations worldwide.

Unique Factors by Region: What to Plan Before You Source For & Execute Installations

North America

North America brings big temperature swings, freeze thaw, ice, and road salt. That environmental mix can loosen any mounting that was not tightened consistently and speed up rust or staining, especially in coastal areas and winter road corridors. Many North American sites are spread out, so a small issue can quickly turn into an expensive return trip. For North American installations, the goal is simple: Consistent tight installs that stay put through demanding conditions.

Europe

Challenges in Europe come down to tight spaces and shared poles. Clearances are limited, equipment stack is crowded, and acceptance expectations can be strict. Compact hardware, clean routing, and repeatable installation steps help crews work faster and avoid rework. Coastal and industrial areas can still be hard on metals, so material choice and surface conditions are critical considerations for European installations.

Asia

Asia covers humid costal zones, heavy rain, and high UV – often with very aggressive rollout schedules. Water resistance and corrosion resistance are baseline requirements. Dense urban installations can add impact and tamper concerns, so toughness and protection are part of the conversation early.

Middle East

The Middle East commonly adds high heat, constant dust, and sand abrasion. Dust and sand can work into gaps and wear on surfaces overtime, so you want mounting methods that stay stable without ongoing adjustment. Coastal areas bring salt air, so projects include corrosion language requirements even when the site is not right on the shoreline.

The Scalable Kit Strategy: Standardize the Method

One of the fastest ways to lose time in global deployments of mounting solutions is to treat every site as a custom problem. A better approach is to standardize a small set of mounting solutions and then kit the brackets and plates around those methods. That keeps the BOM under control, shortens training time, and makes installation quality more consistent across crews and regions.

In practice, most pole and structure mounting needs to fall into three repeatable paths.

- A reusable, common tooling system for when you want a bracket interface that is easy to position and reconfigure

- A high-performance banding system for when you need max clamp force and a clean, low-profile finish

- A band & buckle option with built in tension verification for high flexibility and quick visual confirmation that tension is right

Where Bolt Clamp Casting & Retainers Fit: Bracket Ready Anchors for Pole Mounting

For installers, the best mounting hardware is the kind that reduces steps and minimizes subjective interpretation. Mini & Heavy-Duty Bolt Clamp Casting & Retainers are positioned for easy installation using a single hex key, enabling on person to assemble quickly. It is also positioned for outdoor use with vibration tested performance and corrosion resistant options including 304 & 316 stainless.

interpretation. Mini & Heavy-Duty Bolt Clamp Casting & Retainers are positioned for easy installation using a single hex key, enabling on person to assemble quickly. It is also positioned for outdoor use with vibration tested performance and corrosion resistant options including 304 & 316 stainless.

For global rollouts, another practical detail matters: Adjustability over a lifecycle. Reuse and relocation support retrofit cycles where equipment stacks change on shared poles or when sites are reconfigured for clearance, coverage, or service access.

Three variants, on selection logic:

- Mini Bolt Clamp Casting

- Mini Bolt Clamp Retainer

- Heavy Duty Bolt Clamp Casting

These three variants cover the spectrum of mounting needs: Mini option for compact mounting and heavy-duty options for higher retention requirements and larger diameters.

| Model | Materials | Width Rangle (In) | Length Range (In) | Max Bolt Torque (N.m) | Loop Tensile Strength Range (Lbs) |

|---|---|---|---|---|---|

| Mini Bolt Clamp Casting | 304 & 316 SS | 1/2″ – 5/8″ | 15.7″ – 51.2″ | 10 | 1416-1685 |

| Mini Bolt Clamp Retainer | 304 & 316 SS | 1/2″ – 5/8″ | 15.7″ – 51.2″ | 10 | 494-1416 |

| Heavy Duty Bolt Clamp | 304 SS | 1.1″ | 35.4″ – 106.3″ | 25 | 4720 |

Where Ultra-Lok® Fits: Max Clamp Force & Low-Profile Finish

Finish

Ultra-Lok is a strong option for mounting equipment directly to poles when the priorities are clamp force, repeatability, and a neat, finished profile. Ultra-Lok uses 201 stainless steel band in 1/4 hard material – supporting tighter clamps that can be single or double wrapped depending on the needed retention.

BAND-IT testing for pole-mounted infrastructure showed that Ultra-Lok single wrap installations reach 1,950 lbs of max clamp force with 1/2 inch band and 2,900 lbs with 3/4 inch band.

Where Tru-Lokt TM Fits: Built in Tension Verification and cut to length flexibility

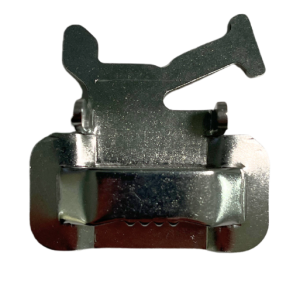

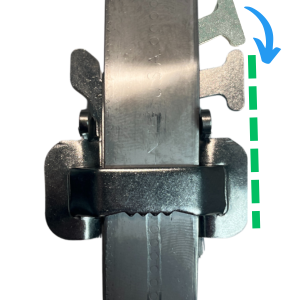

If Ultra-Lok is the high-performance option for max clamp force and a clean low-profile finish, Tru-Lokt is the option for crews who want a familiar band and buckle workflow with built-in tension verification. The key difference is the buckle wing design. As you tighten, the wing collapses and runs parallel when proper tension is reached. That gives installers an instant visual confirmation.

If Ultra-Lok is the high-performance option for max clamp force and a clean low-profile finish, Tru-Lokt is the option for crews who want a familiar band and buckle workflow with built-in tension verification. The key difference is the buckle wing design. As you tighten, the wing collapses and runs parallel when proper tension is reached. That gives installers an instant visual confirmation.

Tru-Lokt also pairs well with roll band because it keeps installs flexible. Roll band can be cut to length for the exact pole diameter or the section of the pole you are working on, ideal for real world conditions where pole widths vary across regions, or even within the same city. Instead of stocking a long list of pre-cut lengths, crews can carry a small number of band widths and cut what they need. This improves flexibility, reduces the number of part variations in the truck, and helps minimize wasted material caused by grabbing the wrong band size.

the exact pole diameter or the section of the pole you are working on, ideal for real world conditions where pole widths vary across regions, or even within the same city. Instead of stocking a long list of pre-cut lengths, crews can carry a small number of band widths and cut what they need. This improves flexibility, reduces the number of part variations in the truck, and helps minimize wasted material caused by grabbing the wrong band size.

In short, Tru-Lokt is the choice when you want a familiar approach, a quick visual confirmation that tension is correct, and the freedom to cut the band to match your needs.

A Practical Global Kit

Installers don’t want to be overwhelmed with several individual solutions. They want a small number of options that over most site realities.

A simple kit structure that scales:

- A compact bolt clamp for tight spaces, lighter equipment, and accessory mounting

- A heavy-duty bolt clamp for higher retention needs and larger diameters

- An Ultra-Lok pole mount for direct to pole installs where max clamp force, low profile finish, and a tamper resistant lock are priorities

- Tru-Lokt buckles paired with roll band for direct to pole installations when you want built in tension verification and the flexibility to cut band to the length of any pole or pole section

This approach keeps BOM manageable, supports both bracket & band-based pole mounting, and gives global teams consistent installation methods that are easy to train, verify, and inspect.

Make Mounting A Process You Can Replicate

Global mounting success is rarely about chasing the best solution. It’s about reducing variation, accounting for exposure, and using methods that crews can repeat across countries and climates. When you define success this way, you naturally select the right tool for the job: Bolt Clamps when you need a bracket ready anchor point, Ultra-Lok when you need max clamping force and a low profile finish, and Tru-Lokt + Roll Band when you want built in tension verification and cut to length flexibility.

If you’re standardizing a global rollout, start by choosing the mounting methods you want crews to repeat, then kit your hardware around those methods. Reduce rework, shorten training time, and achieve consistent installations.

Contact us today to consult on your next project.