How BAND-IT’s Ultra-Lok® Bands Strengthen Irregular Component Joining in Heavy Equipment

September 06.2022 | Essential Infrastructure

When you think of road construction, utility work, or railway maintenance, the image likely includes dozers, excavators, or front-end loaders—those iconic yellow machines built to perform in the harshest environments.

These vehicles operate under relentless stress: extreme heat, abrasive materials, heavy vibration, and unpredictable weather. As emissions standards evolve and system complexity increases, joining components in heavy equipment has never been more challenging—or more critical.

The EGR Cooler: A Critical, Heat-Sensitive Component

One of the most vital emission control components in modern diesel-powered equipment is the Exhaust Gas Recirculation (EGR) Cooler. It lowers the temperature of exhaust gases recirculated back into the engine’s intake, dramatically reducing nitrous oxide (NOx) emissions and helping manufacturers meet increasingly strict regulatory standards.

But this component isn’t easy to install or secure.

EGR coolers feature irregular shapes and are mounted under conditions involving high thermal cycling, constant vibration, and exposure to corrosive exhaust environments.

Why Traditional Joining Methods Fail

Previously, OEMs relied on rigid, bolt-based or weld-based mounting solutions. These approaches often failed due to:

- Differential thermal expansion between metals

- Vibration-related fatigue

- Long installation times

- The need for prototyping or custom brackets

Failures resulted in cracked mounts, compromised emissions performance, and costly downtime for machine operators.

Ultra-Lok® Banding System: Built for the Extremes

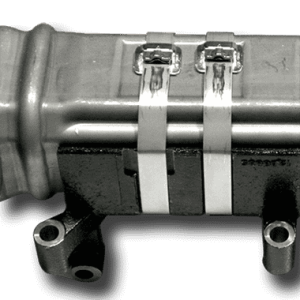

To meet these demanding needs, heavy equipment manufacturers turned to BAND-IT’s Ultra-Lok® Banding System—a high-performance solution that conforms to and clamps around even the most irregularly shaped components.

Banding System—a high-performance solution that conforms to and clamps around even the most irregularly shaped components.

Key Advantages of Ultra-Lok® for EGR Applications:

-

Wraps complex contours with high-retention strength

-

Resists vibration and corrosion, outperforming T-bolt or weld-based clamps

-

Lower profile design reduces spatial interference

-

No custom tooling or prototyping needed—solutions are off-the-shelf

-

Installs 3x faster using the UL4000-D Cordless Tool

-

Improves worker safety by eliminating repetitive motion and cutting hazards

A Closer Look: Field-Proven Performance

Once installed, the Ultra-Lok band tensions around the EGR cooler, conforming to the shape of the bracket and maintaining grip through temperature cycles and vibration. The full-tension locking mechanism sets a reliable joint with minimal installation variation.

Plus:

- Clamp tail is automatically cut by the tool—no excess material

- No sanding or cleanup required

- Reduces operator fatigue and installation variability

This translates to lower total cost of ownership, improved uptime, and enhanced emissions performance—critical for today’s heavy-duty diesel applications.

Applications Beyond EGR

While this case highlights EGR coolers, Ultra-Lok® is ideal for any irregular component where strength, speed, and durability matter. Applications include:

-

Heat shields

-

Insulated pipe assemblies

-

Large cable harnesses

-

Multi-material joint clamping

Ready to Upgrade Your Banding System?

Whether you’re designing next-gen off-road equipment or retrofitting current platforms, BAND-IT’s Ultra-Lok® Band System delivers the proven durability, ergonomics, and engineering confidence needed to succeed in the field.

Explore Clamping Solutions

Contact Our Technical Team for Application Guidance