Fastening Systems That Work Beyond Borders

BAND-IT stainless steel bands and buckles are found across the globe. Infrastructure projects around the world face the same challenges – tight deadlines, safety requirements and pressure to extend the life of public assets. Whether it’s a contractor working on traffic signage in Europe or a utility crew upgrading broadband networks in Asia, the need for reliable fastening systems crosses borders.

For example, in the Netherlands, labor regulations limit the amount of physical effort an installer can expend in a single day. Crews tasked with mounting traffic signs using manual steel banding tools could only complete roughly 30 installs before reaching the threshold. When BAND-IT’s Drill Accessory Banding Tool was introduced, it reduced strain, cut installation time and allowed crews to nearly double the number of signs mounted per day.

No matter where in the world, BAND-IT’s stainless steel banding tools and systems are designed with ergonomics in mind, helping contractors complete more work while reducing the risk of injury. From pedestrian crossings in Europe to telecom retrofits in North America and marine infrastructure in Asia, contractors see the same value: less fatigue, faster installation and reliable results.

The applications themselves are diverse. Stainless steel bands hold street and highway signs in place across Europe. Banding supports utility retrofits in densely populated cities throughout Asia. In coastal regions and marine environments, BAND-IT stainless steel bands resist saltwater corrosion, keeping navigation markers and port infrastructure secure. For government and defense projects, BAND-IT products provide consistent performance under rigorous specifications. The combination of durable materials, proven tools and lasting results builds trust among contractors and procurement teams alike.

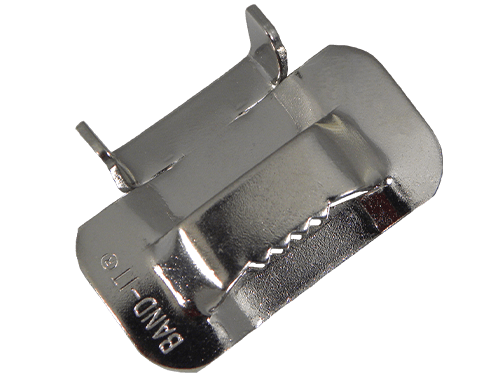

The global reach of BAND-IT is supported by its distribution network and localized service. Crews can access bands, buckles, and installation tools in regional markets, ensuring they have the right hardware when and where they need it. That accessibility matters when projects are running on strict schedules or when compliance requirements demand certified, high-quality components.

No matter the geography, BAND-IT stainless steel fastening systems give contractors and municipalities the same outcome: reliable fastening that saves time, protects workers and keeps infrastructure secure under the toughest conditions.