CDU's & In-Rack Liquid Cooling: Preventing Critical Component Failures in Data Centers

January 05.2026

As artificial intelligence (AI) and high-performance computing (HPC) push rack power higher, the cooling conversation in data center design has shifted toward moving heat more efficiently. Direct-to-chip liquid cooling, rear door heat exchangers, and other liquid approaches are becoming mainstream, and in-rack hose assemblies and expansion (or reservoir modules) have become reliability-critical hardware. UL’s CDU overview highlights the role of Coolant distribution Units (CDU’s) in data center thermal management, reinforcing how central the liquid loop is to uptime.

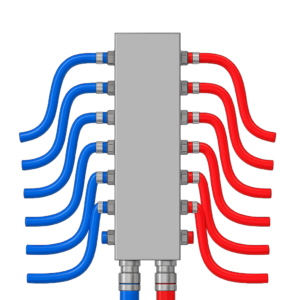

Direct-to-chip cooling loops in data centers involve two primary subsystems: The CDU and the In-Rack Distribution network. The CDU Conditions and pumps the coolant, while the in-rack manifold distributes that coolant to each server’s cold plates. Hose assemblies, clamps and quick disconnects (QDs) belong to the rack distribution side, not the CDU.

For CDU manufacturers, hose fabricators and original equipment manufacturers (OEMs), and for the teams who support them, the difference between a scalable, serviceable liquid platform and a brittle one often comes down to connections and containment – the parts that are easily overlooked unless they fail. BAND-IT has written about the cost of overlooking fastening and repeatability in other safety-critical assemblies, and the same thinking applies here: The fastening method is part of the system, not an accessory.

A useful resource to reference here is OCP’s “Hose and Manual Couplings – Best Practices”. Produced by the OCP Open Rack V3 (ORV3) Blind Mate Liquid Cooling Interfaces group and is explicitly intended to guide hose and manual coupling selection, including how to think about hose loads, routing risks, and clamping.

Cooling Evolution in Data Centers

Liquid cooling is adopted for a straightforward reason; a treated water or water glycol loop can move significantly more heat than air for the same volume, which helps enable higher server density with less fan power, fewer acoustic penalties, and fewer airflow constraints. The CDU is a key part of that architecture in data centers using liquid cooling.

Leading suppliers of liquid cooling ecosystems repeatedly emphasize the importance of standardized connectors, repeatable installs, and materials intended to protect coolant purity over long service life. There aren’t “nice to have”. They’re the difference between a liquid program that scales alongside the rapid changes in the AI market and one that becomes a liability to progress every time a rack is added or serviced.

CDUs and Their Critical Role in Data Center Cooling

A Coolant Distribution Unit (CDU) is the hub that supports cooling for data center equipment, including servers, storage, and direct-to-chip loops. UL describes a CDU as a thermal management device that manages and supplies coolant to equipment. UL notes that CDU’s in data center and information technology equipment (ITE) applications are evaluated under UL/CAN/UEC 623681 unless refrigerants are involved. The CDU never connects directly to servers. Instead, it feeds one or more racks via large diameter supply and return hoses, which interface with each rack’s manifold. The manifold then distributes coolant to the individual servers using smaller QD equipped hoses.

servers, storage, and direct-to-chip loops. UL describes a CDU as a thermal management device that manages and supplies coolant to equipment. UL notes that CDU’s in data center and information technology equipment (ITE) applications are evaluated under UL/CAN/UEC 623681 unless refrigerants are involved. The CDU never connects directly to servers. Instead, it feeds one or more racks via large diameter supply and return hoses, which interface with each rack’s manifold. The manifold then distributes coolant to the individual servers using smaller QD equipped hoses.

Hazards in these systems aren’t limited to electrical. They include exposures of electronics to liquid, pressure and temperature hazards, and the downstream impacts of leaks on safety, reliability, and time. UL’s CDU guidance frames why the CDU category is evaluated under a globally harmonized safety standards for ITE equipment.

If a CDU becomes unstable, even small problems can have effects. A small leak can become a service interruption. A pressure swing can stress seals and joints over time. That is why components that protect pressure stability and leak integrity need to be specified with equal discipline.

Modern Liquid Cooling: The Two Loop Structure

- The CDU (Primary Loop Interface): Manages heat exchange, fluid quality, pumping, pressure control and includes hardware such as expansion tanks, sensors and heat exchangers.

- The Rack Manifold (Secondary Loop): Receives coolant from the CDU and distributes it to servers through small, flexible hose assemblies equipped with quick disconnects and hose clamps.

- Server Cold Plates: Sit directly on CPUs/GPUs and are connected by in-rack hoses.

BAND-IT Clamps are a part of both systems, where hose barb retention, routing security and vibration resistance matter most.

Fastening Components Critical to In-Rack Performance

Fastening and retention are directly relevant to system reliability of in-rack liquid cooling assemblies, especially in:

- Manifold to Server Distribution Hoses: Hose + fitting often quick disconnect & fastening & routing strategy, with lower flow requirements and more frequent servicing.

- CDU-to-Rack Manifold Supply & Return Hoses: Hose + fitting, often a ball-valve coupling, used for less frequent disconnection and more robust mechanical connections.

As platforms are evaluated by data center owners and integrators, they will be judged through the lens of repeatability, serviceability, and interoperability. OCP’s work on hose and coupling best practices is one of the clearest voices pointing in that direction.

In-Rack Hose Assemblies; What They Are and Why They Are Different

“In-rack” hose assemblies are short, flexible connections that route coolant through a rack to devices like the direct-to-chip cold plates or manifolds. These assemblies belong to the rack-level distribution (Secondary Loop), downstream of the CDU The typical assembly includes:

- A flexible hose, often an ethylene propylene diene monomer (EPDM) hose, especially for water-glycol service. EPDM is commonly used in thermal control applications for its temperature flexibility and aging resistance. OCP’s best practices document also notes EPDM as the most common sealing material in thermal control couplings.

- Connection points, including hose barbs and threaded interfaces used to connect manual couplings and manifolds.

- Manual quick couplings, often “non-spill” or “dry break” styles, which are the most common types used for thermal control applications.

Universal Quick Disconnect (UQD) and the Open Compute Project (OCP)

When a coupling is advertised as “OCP compliant” it refers to standards published by the Open Compute Project (OCP). For in-rack quick disconnects, the key document is the Universal Quick Disconnect (UQD) Specification which defines a universal, interoperable interface for noncombustible single-phase water and glycol liquid cooling systems.

The UQD specification includes requirements and targets that matter to OEMs:

- Interchangeability across suppliers for a given size, so plug and socket halves are compatible when built to spec.

- Operating and burst pressure targets, with baseline values in the spec such as 100 psi max operating pressure and 300 psi minimum burst pressure.

- Fluid loss limits on connect and disconnect cycles, defined by size.

- Durability, including a 5,000 make and break cycle expectation for the socket while continuing to meet performance requirements.

- Color coding option, including red or blue, to eliminate errors in routing of fluid lines.

These are the properties that make in-rack service safe, fast, and scalable. UQD connections appear primarily on in-rack manifolds and server cold plates, not CDUs.

Required vs Recommended

OCP specifications are generally voluntary in the legal sense but are on the leading edge of prescribing industry standards and commonly referenced by hyperscalers and integrators who want interoperability and do not want to be limited by proprietary connector ecosystems. Suppliers reflect that reality in their positioning, noting UQD products as complying with OCP and highlighting color identification and 100% helium leak testing.

Why Clamps Matter in UQD Style Ecosystems

The UQD specification defines a hose connection approach on the socket side that includes a hose barb termination option. Some suppliers and interpretations of “Push lock” hose systems emphasize barb retention without clamps, depending on the specific hose and barb design.

However, OCP’s best practices makes at least two specific points that CDU OEM’s and hose assembly manufactures should treat as design inputs, not afterthoughts.

- Tensile loads can show up in real installation, and they change what “Secure” means.

OCP highlights hose assembly tensile strength as a relevant hose property and frames that real systems experience mechanical loads, not just pressure. When tensile load is placed on a hose assembly the termination strategy and tension method matter more.

- Hose creep is real, and clamps can help prevent it.

OCP also calls out compression set and clamping considerations. In plain language, hose materials can relax overtime. That relaxation can reduce sealing force which is one path toward hose creep or leakage at a barb interface.

This is the point many teams miss. A barb can feel secure on day one, but the real question is whether it stays secure after thermal cycling vibration, and time. A properly specified clamp can reduce the risk of creep and improve long-term retention.

Clamps Provide Consistency and Add Security

In high volume deployments, if your assembly outcome depends on technician feel or inconsistent methods, you are betting uptime on human variability. Consistency and process control reduce variation across shifts, lines, and installers.

Clamping also supports test credibility. Many suppliers in this space emphasize helium lead testing and other validation practices. Danfoss, for example, highlights that its UQD offers 100% helium leak testing, and OCP UQD requirements include defined limits for fluid loss and other performance attributes that are affected by joint integrity.

Some hose kit providers also discuss assembly pressure testing as part of quality control, which reinforces the broader industry expectation that connections should pass reliably, not only in a onetime lab set up.

How to Choose a Clamping Approach for CDUs & In-Rack Hose Assemblies

If you are fabricating hose assemblies, the “Right Clamp” conversation should start with a simple question. What are the common failures you need to mitigate? Likely leak paths, loosening over time, and serviceability constraints.

- Pinch Ear Clamps: Generally solid in many applications, but these can introduce localized compression points and can be less forgiving in rework. Tool access can become constrained in tight rack spaces, and the high-profile of the clamp causes snag points in an already tight environment for CDU’s & In-Rack Hose Assemblies.

- Worm Gear Clamps: Familiar and easy to source, but these introduce variation, have protruding hardware, and create snag points.

- Crimped Ferrules: Permanent and high retention, but they require specific equipment and process controls, and they can reduce flexibility for changes or field service.

The Ideal Clamping Solution

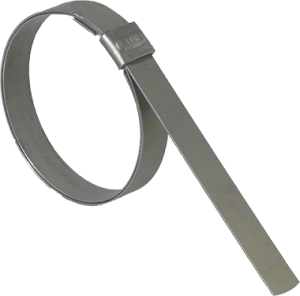

Low profile geometry, repeatable installation, and leak resistance are key for in-rack applications and CDUs. BAND-IT’s Junior® Smooth ID Clamps are designed to reduce leak paths, particularly in thin-walled hose, and support vibration resistance without hammering or crimping.

Low profile geometry, repeatable installation, and leak resistance are key for in-rack applications and CDUs. BAND-IT’s Junior® Smooth ID Clamps are designed to reduce leak paths, particularly in thin-walled hose, and support vibration resistance without hammering or crimping.

BAND-IT also provides a hose clamp performance data sheet that summarizes hydrostatic test-based guidance by hose class and coupling type. The document is designed as a guide and notes its use conditions which helps when building a consistent clamp selection.

Two Additional Opportunities for Improved Equipment Protection

The OCP best practices paper includes guidance that expands fastening beyond the end connection itself.

- Securing hose routing to reduce sharp edge contact: OCP notes that hoses can be damaged by exposure to sharp edges and rough surfaces, and that hose routing can be secured with hose clamps to reduce the chance of contact with sharp edges. That is a direct secondary use case for banding and clamps inside the rack.

- Securing hose sleeving to reduce abrasion risk: When cut resistance or puncture protection is needed, the OCP paper notes options in both hose construction and guarding, including protective covers such as over braids. If you add protective sleeving, the sleeve must stay in place to be effective. BAND-IT has robust fastening methods that keep protective materials secured in harsh duty hose environments, which translate to in-rack abrasion guard retention.

Expansion Tanks: The Quiet Stabilizer Inside Liquid Cooling Platforms

In closed loop liquid cooling, coolant expands and contracts with temperature. Without a buffer, pressure swings stress seals, joints, and pump suction conditions. As a result, many CDU systems incorporate an expansion tank – designed to function as a reservoir during certain service events.

Depending on the design, these vessels can support:

- Expansion compensation, absorbing thermal expansion and contraction so pressure remains stable.

- Reservoir volume, providing a controlled buffer that supports fill or maintenance tasks without opening the loop to the atmosphere.

- Deaeration considerations, because gas in the loop affects stability and pump behavior, and expansion vessel design is frequently discussed alongside deairing challenges.

This is where reliability connects back to safety and certification. CDUs designed for data centers and ITE applications are evaluated under UL/CAN/IEC 623681 per UL’s CDU certification guidance. Expansion tanks only exist in the CDU side of the cooling loop, not in the rack. The rack receives conditioned coolant but does not perform expansion or deaeration.

Requirements for Tank Assemblies

When designing platforms intended to ship globally and run continuously, your tank mounting and retention must handle more than static weight:

- Vibration resistance, including transport vibration and pump induced vibration.

- Handling loads during transportation and installation, including shipping shocks and technician handling.

- Service access, because these are not “install-and-forget” components.

- Space efficiency, because cylindrical vessels are often packaged tightly and bulky brackets complicate layouts in CDUs.

Why Bands are a Strong Approach for Expansion Tanks

A banded strap mount solves several practical problems at once:

- Distributes load around the vessel: Circumferential banding avoids point-loading that stresses plastic tanks or thin wall designs.

- Handles thermal cycling and vibration well: Expansion vessels exist because thermal cycling is expected; mounting should be equally tolerant of that repeated movement.

- Improves serviceability: Straps make replacement and repositioning less invasive than welded mounts and support modular manufacturing and field service models.

Choosing the Right Approach for Tank Mounting

The goal is to eliminate common failure patterns like loosening, inconsistent clamp force, sharp edges, or hardware that complicates service access.

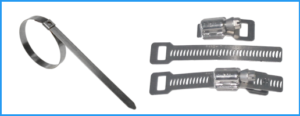

Tie-Lok® Ties

Tie-Lok Ties use a low-profile wrap with a locking mechanism that secures under full tension. They are commonly used where compact retention and consistent tension matter.

Tooling ranges from manual hand-tools to pneumatic production tools, all designed for repeatable, controlled tension and clean cutoff.

Scru-Seal Adjustable Clamps

Scru-Seal Adjustable Clamps use a rack and pinion system with continuous band stock to form clamps of many diameters, tensioned with a screwdriver, with the option to re-tension. These are useful when your design needs flexibility or field adjustability.

How to Decide Between Them?

If your top priority is a low profile with fast, consistent installation, Tie-Lok is the cleaner fit. If your priority is adjustability and the option to re-tension, Scru-Seal earns consideration.

Key Takeaways: CDUs, In-Rack Hose Assemblies & BAND-IT Clamping

The best liquid cooling platforms feel boring when they work, that is the goal!

If you design for interoperability from day one using OCP UQD guidance and treat fastening as a part of the system, you reduce redesign risk later. OCP’s hose and coupling best practices guide is a strong checklist for design consideration, including tensile loads, hose creep, and routing protection.

BAND-IT supports OEM teams building those systems with fastening solutions that align to the same priorities: Repeatable installation, low profile finish, and durable retention for hose assemblies, routing, and expansion reservoir mounting. Contact us today for more details!